Plant

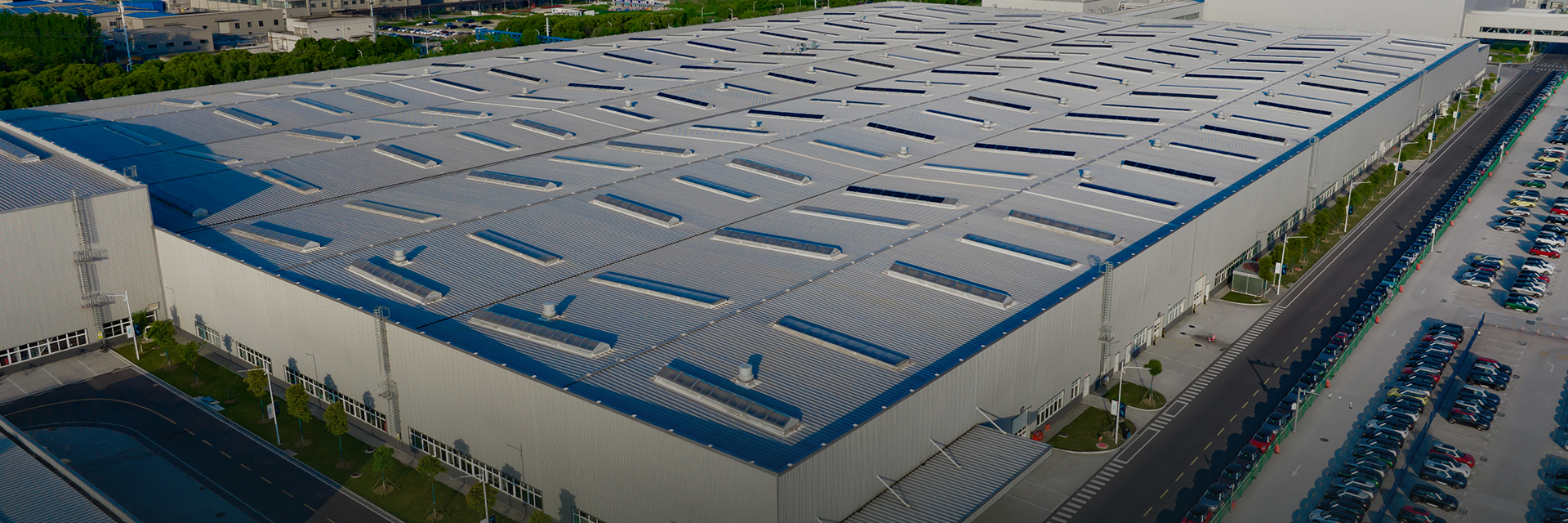

Spotlight Automotive Plant covers an area of 930 mu, with a construction area of approximately 280,000 m2, The plant is equipped with four major workshops: stamping, body, paint, and assembly, as well as analysis center and pack workshop, test track and other facilities. The plant is based on the concept of “intensive land use, intelligent manufacturing, energy saving and environmental protection”, and promotes products, technologies, and plants simultaneously. Through the application of innovative technologies and scientific layout planning, each process fully integrates the advanced production concepts of BMW and Great Wall, applies the cutting-edge international production technology and quality management system, making it a benchmark factory that truly meets global regulations and market requirements.