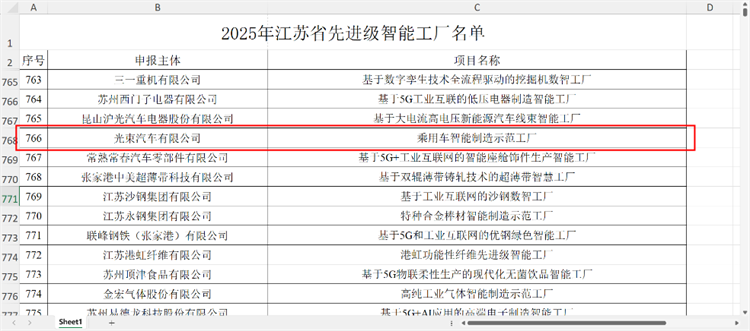

Spotlight Awarded 2025 Jiangsu Provincial Advanced Intelligent Plant

Jul 01, 2025

Recently, Spotlight was recognized as “2025 Jiangsu Provincial Advanced Intelligent Plant”. This is the second time the plant has been awarded the provincial “Intelligent Plant” honor, following its designation as a “Jiangsu Provincial Intelligent Manufacturing Plant” in 2024.

Intelligent plants are a crucial direction for the digital transformation and upgrade of manufacturing, and they are key for companies to enhance competitiveness and achieve sustainable development. At the 2024 World Intelligent Manufacturing Conference, the “National Intelligent Plant Graded Cultivation Action” was officially launched, aiming to build a comprehensive system from foundational, advanced, excellent, to leading intelligent plant levels. Advanced Level Intelligent Plant are required to achieve digital and networked processes, including digital R&D and design, precise control of key processes, and seamless integration of multiple management stages. Companies must complete intelligent construction across production operations, production management, and operations management, with at least 15 intelligent manufacturing scenarios. Their intelligent manufacturing capability maturity must reach Level 2 or above in the "Intelligent Manufacturing Capability Maturity Model" (GB/T 39116-2020).

Spotlight’s achievement as an Advanced Intelligent Plant in Jiangsu Province was due to the company's forward-thinking investments and planning in information management, intelligent production technologies, and quality management systems. According to the “Jiangsu Provincial Intelligent Plant Graded Construction Element Conditions (2025 Edition),” Spotlight plant has covered four areas: R&D and design, production operations, production management, and operations management, with the construction of 18 scenarios. The self-assessed level of the intelligent manufacturing capability maturity has reached Level 3 in the “Intelligent Manufacturing Capability Maturity Model” (GB/T 39116-2020).

Benchmark Plant that Truly Meets Global Regulatory and Market Requirements

Spotlight Automotive's production base is in the Economic Development Zone of Zhangjiagang City, covering an area of 930 acres with a construction area of 280,000 square meters and an annual standard planned capacity of 160,000 vehicles. The plant houses five major workshops: Stamping, Body, Painting, and Assembly - as well as an analysis center, PACK workshop, and a test track. Aligned with the principles of "intensive land use, intelligent manufacturing, and energy saving and environmental protection," the plant synchronizes the development of products, processes, and facilities. Through the adoption of new technologies and strategic layout planning, each process fully integrates the advanced production concepts from BMW Group and Great Wall Motors, utilizing cutting-edge international manufacturing technologies and quality management systems. This makes it a benchmark plant that truly meets global regulatory and market requirements.

Reliable Information Systems Enable Intelligent and Efficient Production Process

Throughout the production process, the plant has fully advanced hardware intelligence and software informatization. It utilizes multiple information systems such as the APS system, LES system, MES system, PDA, IoT system, and Data Lake. These systems encompass production planning, logistics management, production process control, and data analysis. Demonstrative applications have been deeply implemented in several scenarios, including automatic generation of scheduling plans, monitoring and early warning of production equipment, online control of product quality, and intelligent optimization of warehousing and distribution. This allows for real-time monitoring, data analysis, and quality management of the entire production process. All workshops are equipped with intelligent production, transportation, warehousing, and inspection equipment, ensuring an intelligent, efficient production process and stable, reliable product quality.

Environmentally Friendly and Sustainable Green Plant Ecosystem

Spotlight embraces sustainability as a core strategic principle, dedicated to providing customers with products that originate from a green plant and green supply chain. The company adheres to a "regeneration priority" approach, implementing sustainable practices across all stages, from raw material procurement and production to usage and recycling. In April of this year, the first phase of the plant's 12MW photovoltaic project was successfully connected to the grid and put into operation. It is expected to generate 12.6 GWh annually, potentially reducing carbon emissions by approximately 6,500 tons each year—equivalent to the carbon reduction achieved by reforesting 26,000 acres. With these actions, Spotlight is making a tangible contribution to a greener future for the planet.

With a focus on “intelligence” to enhance quality, looking ahead, Spotlight will continue to drive innovation and application of intelligent manufacturing technologies, steering the company towards greater efficiency, environmental sustainability, and intelligence. This effort aims to contribute to the high-quality development of the manufacturing industry in Jiangsu Province and across China.