Spotlight Automotive: Global Intelligent Manufacturing System Supports the Launch of the New Electric MINI JCW

Apr 14, 2025

(Nanjing, Jiangsu) – On April 14, the electric MINI JCW "Curved Road Masters" officially hit the market, these models are the electric MINIs produced by Spotlight Automotive for the global market. As these new models become icons in the compact car market with their style, performance, and appeal, they represent the sophisticated fusion of BMW Group's global quality standards and localized innovation within Spotlight's intelligent manufacturing system.

Building Global Standards, Forging a Robust Manufacturing System

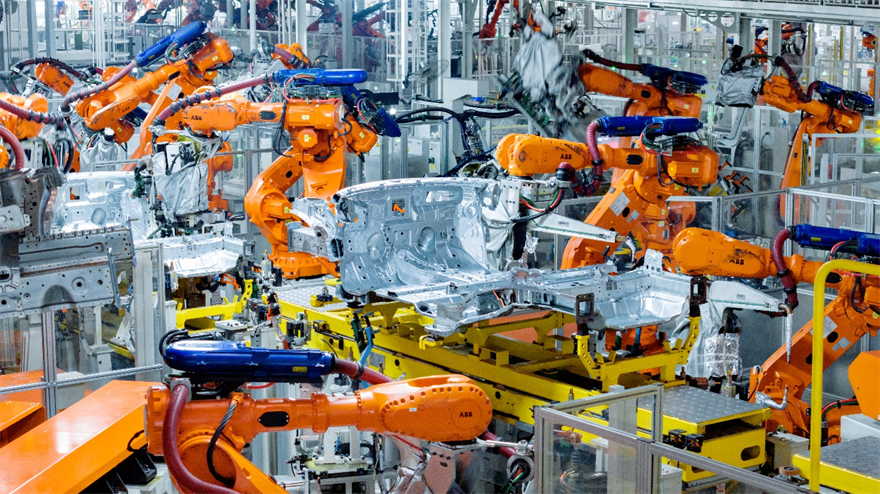

As a Sino-foreign joint venture, Spotlight has inherited BMW Group's century-long manufacturing expertise while leveraging China's rapidly evolving new energy industry benefits. Through localized innovation, the company has achieved excellence in both production efficiency and product quality. Here, efficiency, precision, and automation have become synonymous with every production process. The driving force behind this high-efficiency production is the intelligent "brain" of the plant. Comprising 48 information systems, it covers everything from product definition to engineering development, from customer orders to automatic scheduling, transforming them into customer needs—all within just seven days. Spotlight CEO, Louis Li, stated, "In 2024, Spotlight achieved production and profitability within the same year, showcasing the remarkable 'Spotlight Speed' and creating an industry miracle."

From the orderly distribution of parts by the AGV logistics system to the precise operations of robotic arms in the body workshop, Spotlight ensures that every electric MINI JCW meets BMW Group's unified global quality standards through top-tier automation and standardized production processes. Notably, the production of the new electric MINI JCW models incorporates a comprehensive EHM equipment health management system and a visual inspection system. These advanced technologies enable real-time monitoring of every production phase—whether welding, gluing, or whole vehicle identification—facilitating 100% online surveillance. With cloud storage and VIN tracking, every car’s quality is traceable from production to delivery, ensuring compliance with BMW Group's stringent global standards. In 2024, Spotlight was honored with the "Jiangsu Province Intelligent Manufacturing Factory" title and successfully listed in the Ministry of Industry and Information Technology's national directory of 5G factories.

3 million Kilometers of Extreme Testing Redefines Quality Standards

In the research and validation stages, BMW Group has spared no effort, successfully completing the "three years, three extremes, 3 million kilometers" testing regime. The new vehicles have accumulated over 3 million kilometers in global test mileage—equivalent to four round trips between the Earth and the Moon. During the three-year testing period, these vehicles underwent numerous tests for high temperatures, high humidity, and extreme cold conditions around the world.

In China, the localization verification and testing process has been equally meticulous, aligning closely with global standards. The testing routes for the two new models spanned the vast expanse of China, from the frigid Yakeshi in the north to the scorching Turpan in the west, bustling Shanghai in the east, and the humid Hainan Island in the south, including mega-cities like Beijing and Chongqing. In terms of durability testing alone, the total test mileage in mainland China exceeded 1.72 million kilometers. Additionally, significant custom tuning was performed on these two new models, building upon the electric MINI foundation, with specialized testing covering 150,000 kilometers. The vehicles were then transported to Germany's Nürburgring racetrack for dynamic testing to thoroughly validate their handling capabilities.

Regarding the charging experience, which is of utmost concern to Chinese users, MINI conducted extensive testing across regions like Beijing-Tianjin-Hebei, Sichuan, Guangdong, and Jiangsu-Zhejiang. Over 1,100 comprehensive charging tests were performed, verifying compatibility with 30 different brands of charging stations. This ensures adaptability to various climate conditions and usage scenarios, allowing MINI users in any region to charge with confidence. As a result, Chinese customers can enjoy a more localized and higher-quality MINI JCW product, truly reflecting the brand's expertise in creating exceptional small cars.

Green Manufacturing Upholds Sustainability Commitment

Spotlight has integrated environmental principles throughout its entire manufacturing process. The installation of a 12-megawatt photovoltaic system at the plant stands as a key measure for implementing renewable energy. By utilizing clean energy and treating and recycling industrial wastewater, Spotlight has significantly reduced carbon emissions during manufacturing. Furthermore, the innovative application of bio-based eco-friendly coatings has ensured that VOC emissions in the painting workshop are well below national standards, fully honoring Spotlight's commitment to sustainable development. "The goal of intelligent manufacturing is to harmonize efficiency with environmental responsibility," stated Louis Li. The company remains steadfast in its promise of sustainable green manufacturing and has successfully joined the United Nations Global Compact.

From a classic British brand to a leading example of intelligent manufacturing in the Yangtze River Delta, Spotlight Automotive is injecting new energy into the upgrade of Jiangsu's auto industry with its "global standards and integrated innovation." This effort supports the local consolidation of resources and the development of the regional industrial layout. As the new electric MINI JCW introduces the ultimate go-karting excitement of the electric era, it is backed by 3 million kilometers of quality validation, comprehensive quality assurance, and rigorous global intelligent manufacturing standards. Together, these elements embody the core principle that "excellence in products stems from an advanced, reliable manufacturing system."